Indexes that must be Known in Metal Tensile Test

Tension is a simple mechanical property test. Within the test gauge, the stress is uniform, the measurement of stress-strain and its performance indexes is stable, reliable and convenient for theoretical calculation. Through the tensile test, the most basic mechanical properties in the process of elastic deformation, plastic deformation and fracture of materials can be measured, such as positive elastic modulus E and yield strength σ 0.2. Yield point σ s. Tensile strength σ b. Elongation rate after fracture δ And reduction of area ψ Wait. Mechanical property indexes obtained in tensile test, such as e σ 0.2、 σ s、 σ b、 δ、ψ It is the inherent basic properties of materials and the main basis in engineering design.

Tensile test is the most common test in metal mechanical property test. The measurement results of the same material through different tensile test processes are not necessarily the same. What factors are affecting the tensile test?

1. Sampling Position and Method

Due to the uneven distribution of composition, organization, mechanism, defects, processing deformation, etc. in the materials, there are differences in different parts of the same batch or even the same product. Therefore, when cutting samples, it shall be carried out in strict accordance with the provisions of the standard.

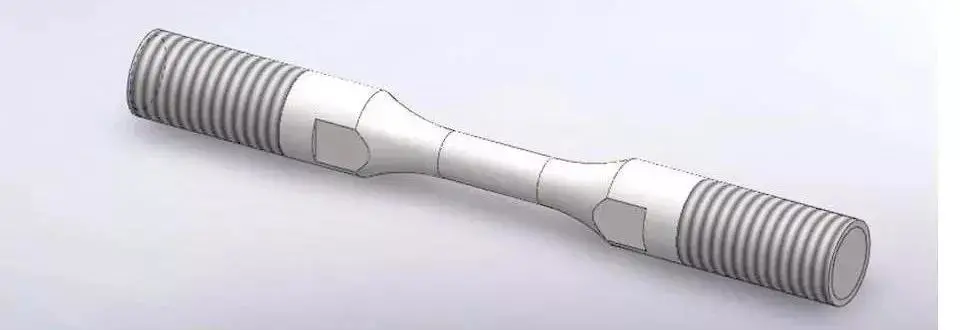

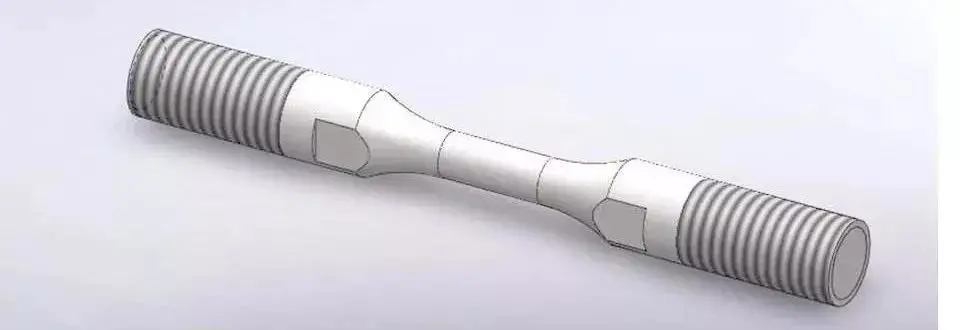

Three dimensional drawing of tensile specimen

2. Test Equipment

The test equipment directly affects the accuracy and authenticity of the result data, so the test machine must be within the validity period of verification.

3. Impact of Test Environment

The test environment mainly includes the influence of ambient temperature and the selection of clamping apparatus.

Spherical support collet

4. Selection of Test Methods

The test methods mainly include the clamping method, tensile rate, tensile cross-sectional area and the measurement method of pattern size. When selecting the size of the measurement pattern, it is appropriate to select the outer diameter micrometer, vernier caliper or vernier caliper for rectangular sample.

In addition, due to different subjective factors and operation skills, it will also bring errors to the measurement results. Therefore, the inspectors should pass the strict training and carry out the test according to the standard method.