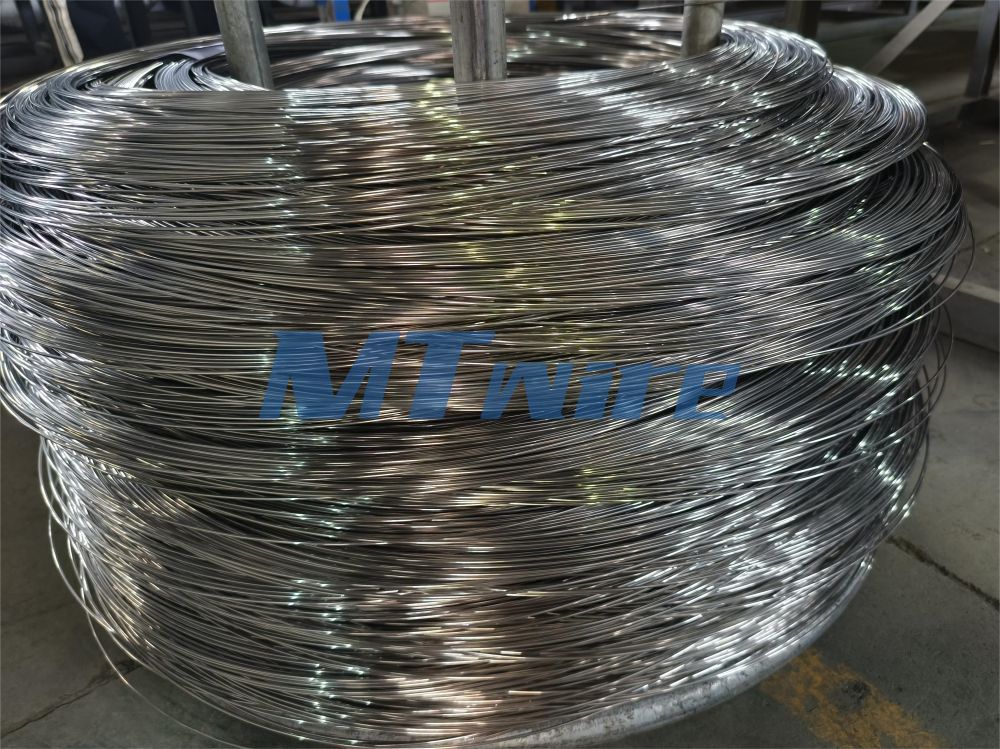

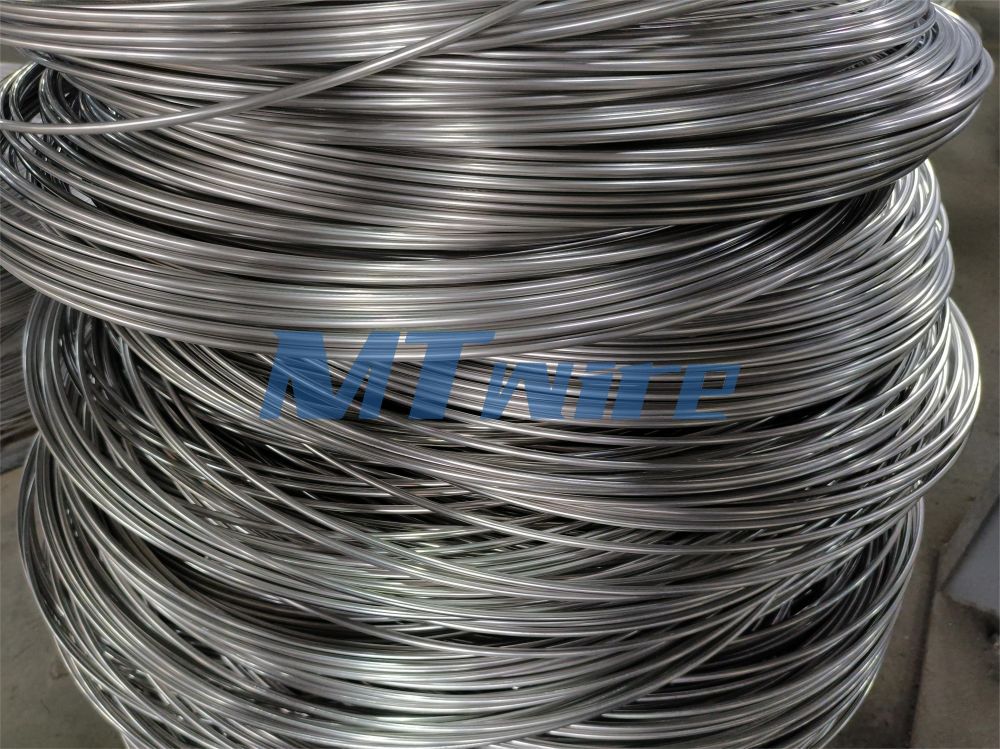

-- From Raw Material to Precision Product Understand the intricacies of the stainless steel wire production process, each step from raw material preparation to final inspection and packaging, and the importance of smelting, hot rolling, pickling, drawing, ann......

Read More-- Step-by-Step Guide to Production ProcessesTake a look at the complex process of manufacturing stainless steel wire, from raw material preparation to final inspection and packaging. Each step is critical to ensuring the quality and performance of the final p......

Read More-- Producing high-quality stainless steel wireThis article delves into the manufacturing process of stainless steel wire, from selecting raw materials to the final product. It highlights the intricate steps involved, including melting, hot rolling, annealing, ......

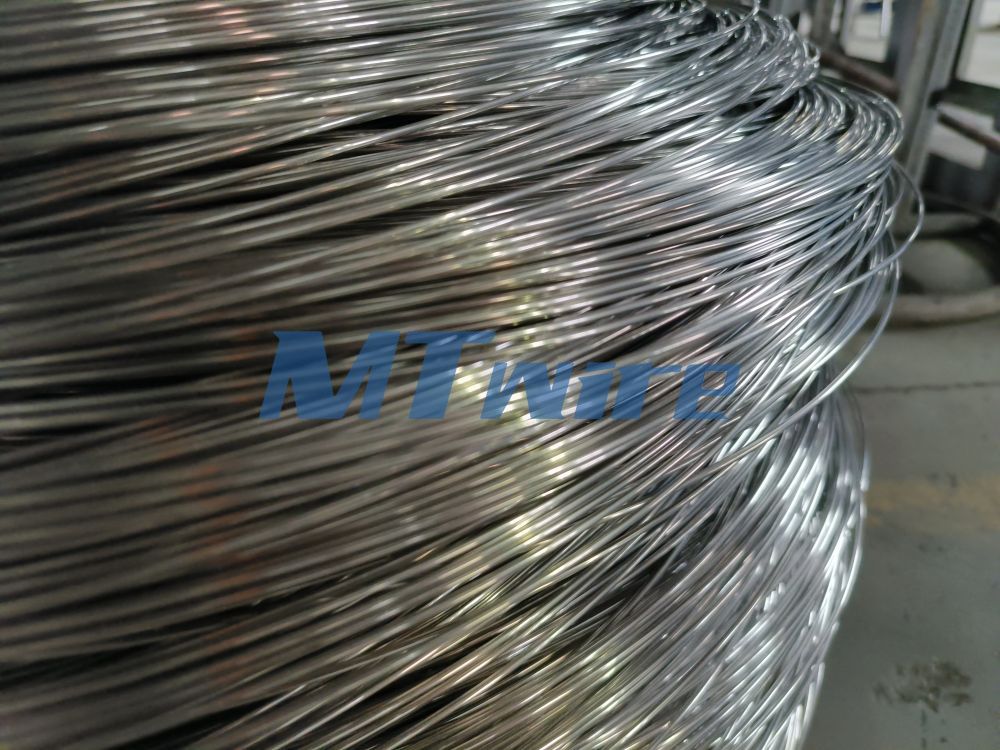

Read More-- Essential Attributes for Diverse ApplicationsThe three main qualities of stainless steel wire are corrosion resistance, strength and sustainability. Stainless steel wire is used in a wide range of applications in both industry and everyday life.Corrosion re......

Read MoreThis article highlights the top three qualities of stainless steel wire: corrosion resistance, strength, and sustainability. It explains how these properties contribute to the material's widespread use in various demanding applications. Corrosion resistanceCo......

Read MoreMedical Applications of Medical WireAs a key medical consumable in the modern healthcare industry, medical wire plays a vital role in a wide range of clinical operations. From surgical suturing and tissue repair to catheterization, medical wires are used in a ......

Read MoreHigh Weldability of Nickel Alloy ER625 Welding WireMTSCO is a factory complex dedicated to producing products that satisfy our customers. Today, we would like to introduce our Nickel Alloy ER625 welding wire, a material that excels in high-end applications. Th......

Read MoreNickel Alloy 825 is a nickel-based alloy known for its excellent corrosion resistance and high temperature performance. Its alloy composition includes elements such as Nickel, Chromium, Iron and Copper, giving it excellent stability and corrosion resistance in......

Read MoreWith the rapid development of industry, stainless steel wire has gradually become an indispensable and important material for various industries, and its excellent performance has been widely used in construction, electric power, medical, automotive and electr......

Read More01丨Welding Wire for Submerged Arc WeldingIn the process of submerged arc welding, the welding wire serves the dual purpose of filling metal and introducing alloying elements into the weld while participating in metallurgical reactions that protect and treat t......

Read MoreStainless steel wire (or stainless steel products), is a limited number of rare alloying elements into the steel base, the formation of different characteristics of the product with special purposes. Improve the resource reuse of stainless steel products, with......

Read MoreWelding wire is a very important material in metal welding. Stainless steel and nickel alloy wires, for example, have a wide range of applications in metal welding, especially in MIG, TIG, and submerged arc welding, and are the most widely used welding materia......

Read More