Stainless Steel Wire: From Raw Material to Finished Product

-- Producing high-quality stainless steel wire

This article delves into the manufacturing process of stainless steel wire, from selecting raw materials to the final product. It highlights the intricate steps involved, including melting, hot rolling, annealing, and cold drawing, and underscores the significance of each stage in producing high-quality stainless steel wire.

The many qualities of stainless steel are second only to the many forms this critical material can take and the subsequent applications that can be realized using these forms, and next we will cover the manufacturing of one of the most widely used forms of stainless steel - steel wire.

The first step is to select the raw material. Stainless steel is an alloy composed primarily of iron and chromium, but can be mixed with other elements such as nickel, molybdenum and carbon. All of these elements will give the finished material the qualities needed for any given application.

Once the correct quantities of these different elements have been identified and found, they will be placed into an electric arc furnace where they will begin to melt at extremely high temperatures. When fully melted, they are evenly mixed together to form a completely homogeneous molten stainless steel. The mixture is then poured into a mold and cooled until a solid plate, also known as a billet, is formed.

Next comes hot rolling. Each slab passes through a series of heated rolls that work to elongate the material while reducing its thickness. At the end of this grueling process, the material is in the form of long strips called "bars".

These bars then move on to the next stage of the long and complex process of producing stainless steel wire. After being heated to a precise temperature, the bars are annealed, which is essentially slow and controlled cooling. The annealing process reduces the hardness of the alloy while releasing internal stresses; this in turn makes the bar more ductile, which in turn prepares it for the next stage of the process, cold drawing.

Cold drawing involves a series of dies through which the annealed bar is passed under high tension. Each die in the series is smaller than the previous one, so during the process the length of the bar increases and the diameter decreases until the specified diameter is reached.

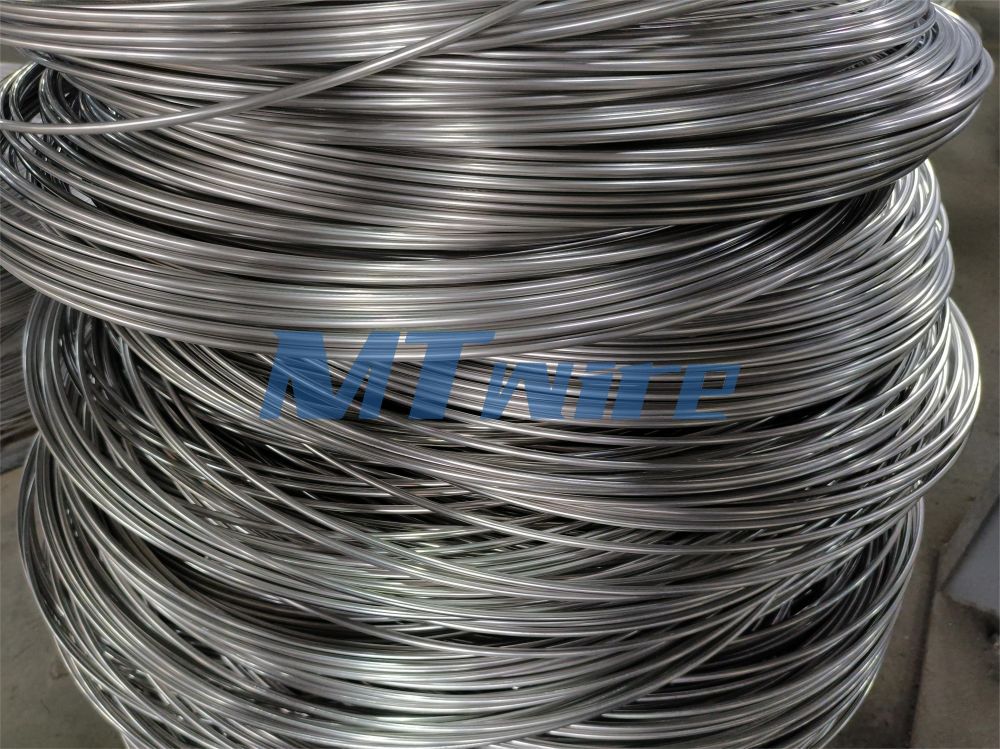

Now that the raw material has been transformed into stainless steel wire, all that remains to be done is to apply the necessary surface treatments, such as lubricating the wire to reduce friction, facilitate further processing or enhance its corrosion resistance. The finished stainless steel wire can then be cut into precise lengths, which are usually rolled into coils for efficient storage and transportation.