The complex craft of making stainless steel wire

-- Step-by-Step Guide to Production Processes

Take a look at the complex process of manufacturing stainless steel wire, from raw material preparation to final inspection and packaging. Each step is critical to ensuring the quality and performance of the final product.

The production process of stainless steel wire generally includes the following steps:

1. Raw material preparation: the stainless steel raw materials to the factory, the necessary inspection and screening, to remove surface defects and impurities.

2. Smelting and casting: the ingot billet into the electric furnace or vacuum melting furnace for melting, will be transformed into liquid stainless steel, and poured into the casting mold for casting. After casting, the castings will be sent to the mill for the first hot rolling.

3. Hot rolling: the castings are sent to the multi-pass hot rolling mill, through continuous heating and rolling, it will gradually deform into a thin and continuous stainless steel strip. Hot rolling process, the need for cooling and evacuation of lubricants and other auxiliary processes.

4. Pickling: In order to remove surface oxidized skin, rust and surface defects, it will be treated by pickling process. Generally use immersion in an acidic solution for reaction, such as sulfuric acid, hydrochloric acid and so on.

5. Drawing: the pickled stainless steel strip into the drawing machine, through a number of stretching and pressing, so that it gradually thin and obtain the required diameter and mechanical properties.

6. Annealing: In order to eliminate the stress in the drawing process, improve the organizational structure and mechanical properties of stainless steel, the drawn stainless steel wire annealing treatment. Annealing method is usually continuous annealing or salt bath annealing, temperature and time according to the requirements of different products to control.

7. Surface treatment: the annealed stainless steel wire surface treatment, such as pickling, polishing, plating, etc., in order to increase its finish and corrosion resistance.

8. Bending and cutting: Bend or cut the stainless steel wire according to customer's requirements to get the required shape and length.

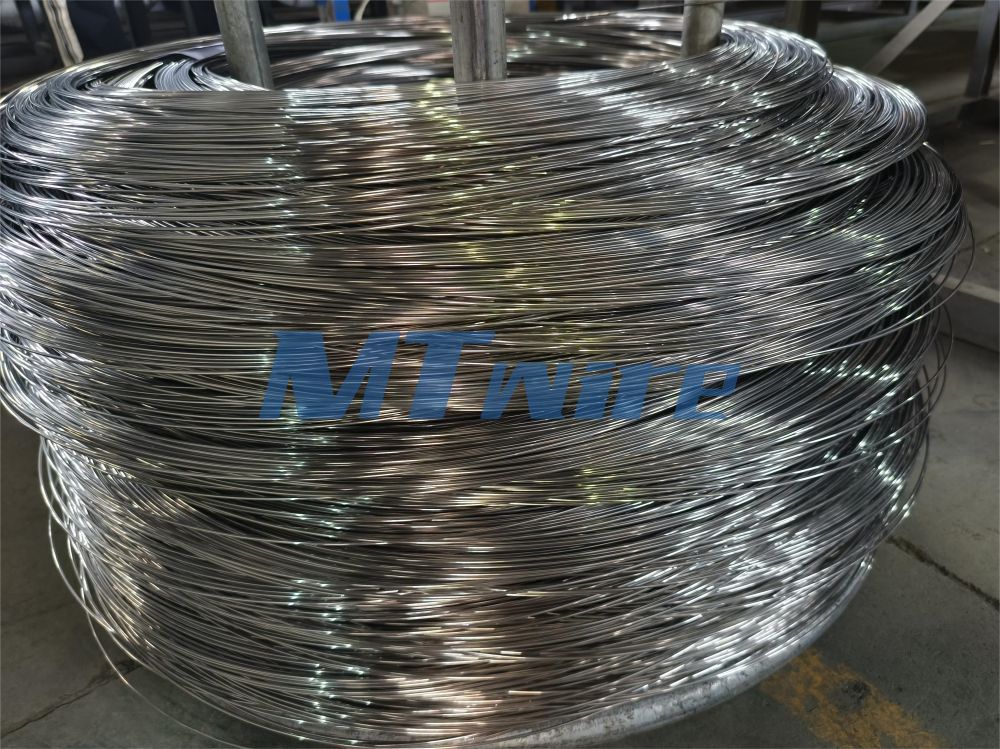

9. Inspection and packaging: The finished stainless steel wire is subjected to the necessary quality inspection, including appearance quality, mechanical properties, chemical composition and dimensions. Qualified products for packaging, usually using paper plates, cartons or trays, and labeling.