The superlative properties of stainless steel wire

-- Essential Attributes for Diverse Applications

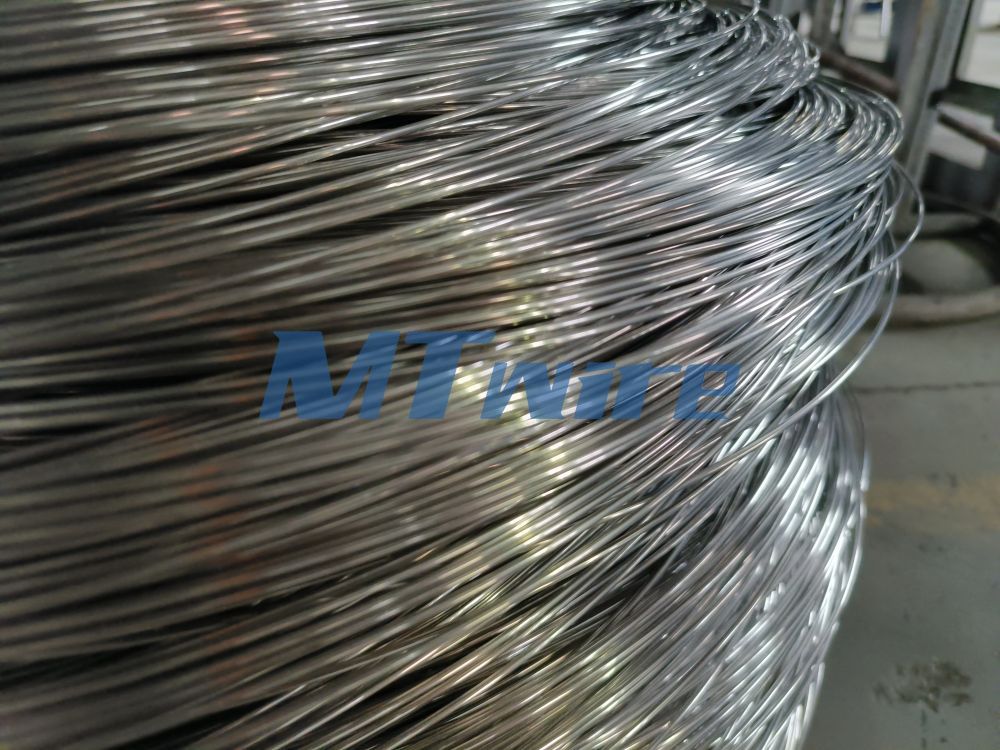

The three main qualities of stainless steel wire are corrosion resistance, strength and sustainability. Stainless steel wire is used in a wide range of applications in both industry and everyday life.

Corrosion resistance

Stainless steel wire has excellent corrosion resistance. According to the definition of the national standard, the chromium content in stainless steel must be at least 10.5%, which makes the steel surface form a layer of "passivation layer". This layer protects the steel from rusting by reacting with oxygen in the environment. An increase in chromium content makes the passivation layer more stable and thus improves corrosion resistance. The addition of chromium, nickel, manganese and molybdenum can also further enhance the corrosion resistance of stainless steel. Stainless steels containing higher levels of chromium and molybdenum perform particularly well in harsh environments such as the sea.

Strength

The high strength of stainless steel wire is widely used in the fields of construction, aviation and automobile, etc. The tensile yield strength of 304 grade stainless steel wire is about 210 MPa, which can be increased to 1050 MPa through cold working treatment, and some special stainless steel alloys after heat treatment, the tensile strength even reaches 1730 MPa. This high strength not only improves the durability of the material, but also ensures the reliability of stainless steel wire under high pressure and high temperature environments. High pressure and high temperature environment reliability.

For example, high-strength stainless steel is often used in power plants and petrochemical plants to ensure the safety and long life of the equipment.

Sustainability

According to the International Stainless Steel Forum (ISF), stainless steel is typically made from approximately 70% scrap metal, which reduces waste emissions and saves resources. The 100% recyclability of stainless steel means that not only can it be reused, but it does not produce hazardous substances. Most importantly, stainless steel is produced and recycled without the use of large quantities of rare elements, further reducing the environmental impact.

Versatile application scenarios

Stainless steel wire has a wide range of applications in several fields. For example, in the construction sector stainless steel wire is often used as reinforcing steel to provide additional structural strength. In the medical field, stainless steel wire is used to make surgical tools and implants, which are harmless to the human body due to its non-rusting characteristics. And in marine engineering, stainless steel wire is used in the manufacture of ships and offshore platforms, able to withstand the harsh marine environment corrosion.

Unique Properties of Specialty Stainless Steels

Different types of stainless steel have unique properties. For example, duplex stainless steel combines the advantages of austenitic and ferritic, both good corrosion resistance and high strength, suitable for seawater chloride ion pitting environment. Super austenitic stainless steels such as 904L and 317L, with higher chromium and nickel content, offer excellent corrosion resistance and are suitable for extreme environments.

In summary, with its excellent corrosion resistance, high strength and high degree of sustainability, stainless steel wire plays an integral role in a number of fields. These properties not only make stainless steel an important material in industry and everyday life, but also demonstrate its vital role in promoting sustainable development.