Wire Decoding: Understand All Kinds of Wire in One Article

In our everyday life and industrial production, various types of wire, made from materials like stainless steel, nickel alloys, and carbon steel, play crucial roles. Have you ever felt puzzled by the wide variety of wire types, finding it hard to distinguish their characteristics and uses? This article will detail each type, helping you fully understand their unique properties and applications.

Spring Wire:

Noted for high plasticity and superb fatigue strength, it maintains excellent performance even in harsh environments. Besides, spring wire offers great heat resistance and an appealing surface.

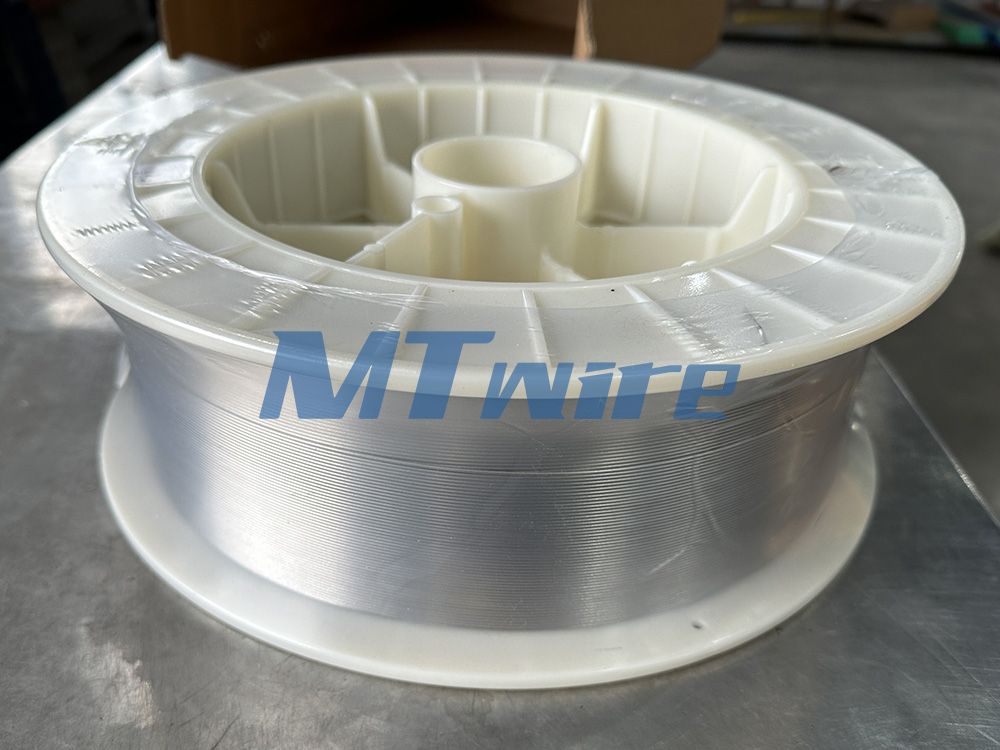

Welding Wire:

This key industrial material finds use in sectors like shipbuilding, chemical industries, power generation, oil refining, and automobiles. It includes types like MIG (Metal Inert Gas Welding), TIG (Tungsten Inert Gas Welding), SUB (Submerged Arc Welding), and COR (Cored Electrode Wire).

Shaped Wire:

Thanks to its easy molding and processing characteristics, it's vital in the manufacture of products like antennas, headphone wires, watch straps, and wiper wires.

Nickel Alloy Wire:

Boasting excellent corrosion resistance and thermal stability, it's an ideal choice for high-temperature, high-pressure, and harsh environments.

Medical Wire:

A critical component in numerous medical fields such as medical devices, instruments, and diagnostic equipment. It often meets stringent biocompatibility and safety standards.

Electrolytic Polishing Wire:

This wire is widely used in creating high-quality decorative items and everyday products. With a bright surface, uniform hardness, and excellent corrosion resistance, it's becoming more prevalent.

Weaving Wire:

Known for its shiny surface, uniform hardness, and high corrosion resistance, it's widely employed in producing woven wire mesh and conveyor belts used in chemical, food processing, oil refining, kitchenware, and paper industries.

Cold Heading Wire:

This wire, with excellent formability, low processing stress, and good quality, is extensively used. It offers low work hardening, causes less die wear, and displays lower magnetism after cold forging.

Nail Wire:

Popular due to its excellent corrosion resistance and formability. Its low magnetism and special lubrication coating help extend the mold's service life and boost productivity.

Tie Wire:

Stainless steel tie wire is commonly used in daily life. It extends the service life by reducing frequent replacements. It offers a smooth, clean surface, and consistent flexibility, making it easy to work with.