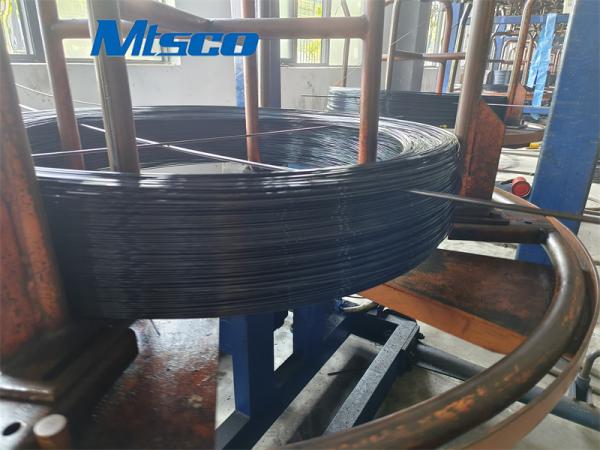

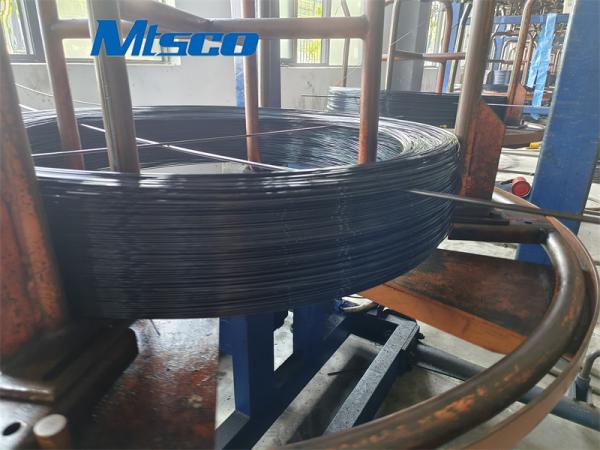

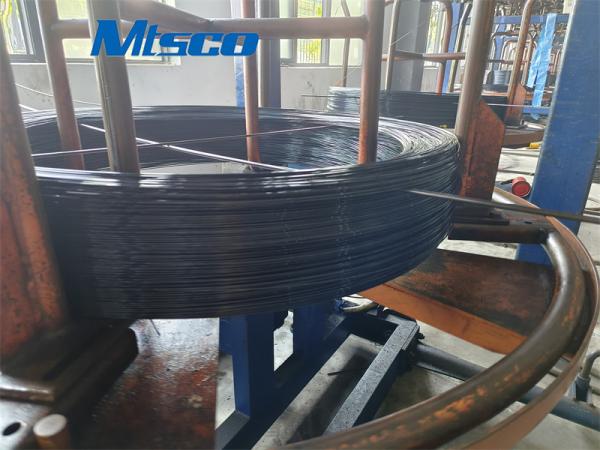

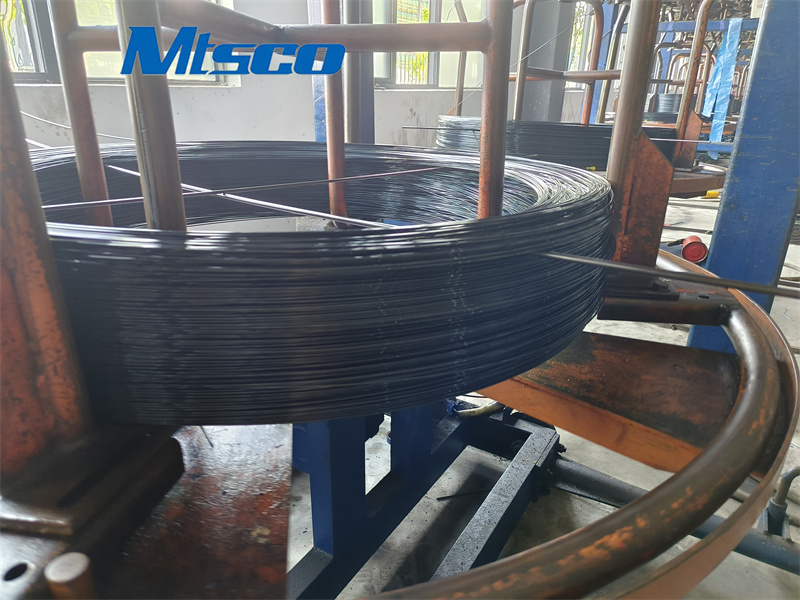

Carbon Steel Spring Wire

ASTM A228 72A / 72B 82A / 82B High Carbon Steel Spring Wire For Music / Piano Wire Furniture Springs

72B has a higher manganese content than 72A. The increase of manganese content improves the mechanical property, strength and toughness of steel wire. Therefore, 72B steel wire is more elastic. 72B high carbon steel wire is affordable, sturdy and durable. It is generally formed by drawing and has a smooth surface.

ASTM A228 72A / 72B High Carbon Steel Spring Wire For Music / Piano Wire

| Product name | Carbon Spring Steel Wire | |||

| Product material | UNS 1065, 1070, 72B, 72A, 82A, 82B, 79A | |||

72B has a higher manganese content than 72A. The increase of manganese content improves steel wire's mechanical property, strength and toughness. Therefore, 72B steel wire is more elastic. 72B high carbon steel wire is affordable, sturdy, and durable. It is generally formed by drawing and has a smooth surface.

It is commonly used in bridges, railways, and various construction projects to manufacture galvanized steel wire strands, hard drawn steel wires, wiping ropes, unimportant mechanical parts that do not require heat treatment, general weldments, piano wires, etc

|  |

Features of 72A/72B carbon steel spring wire:

Application:

Quality Control:

Company Profile

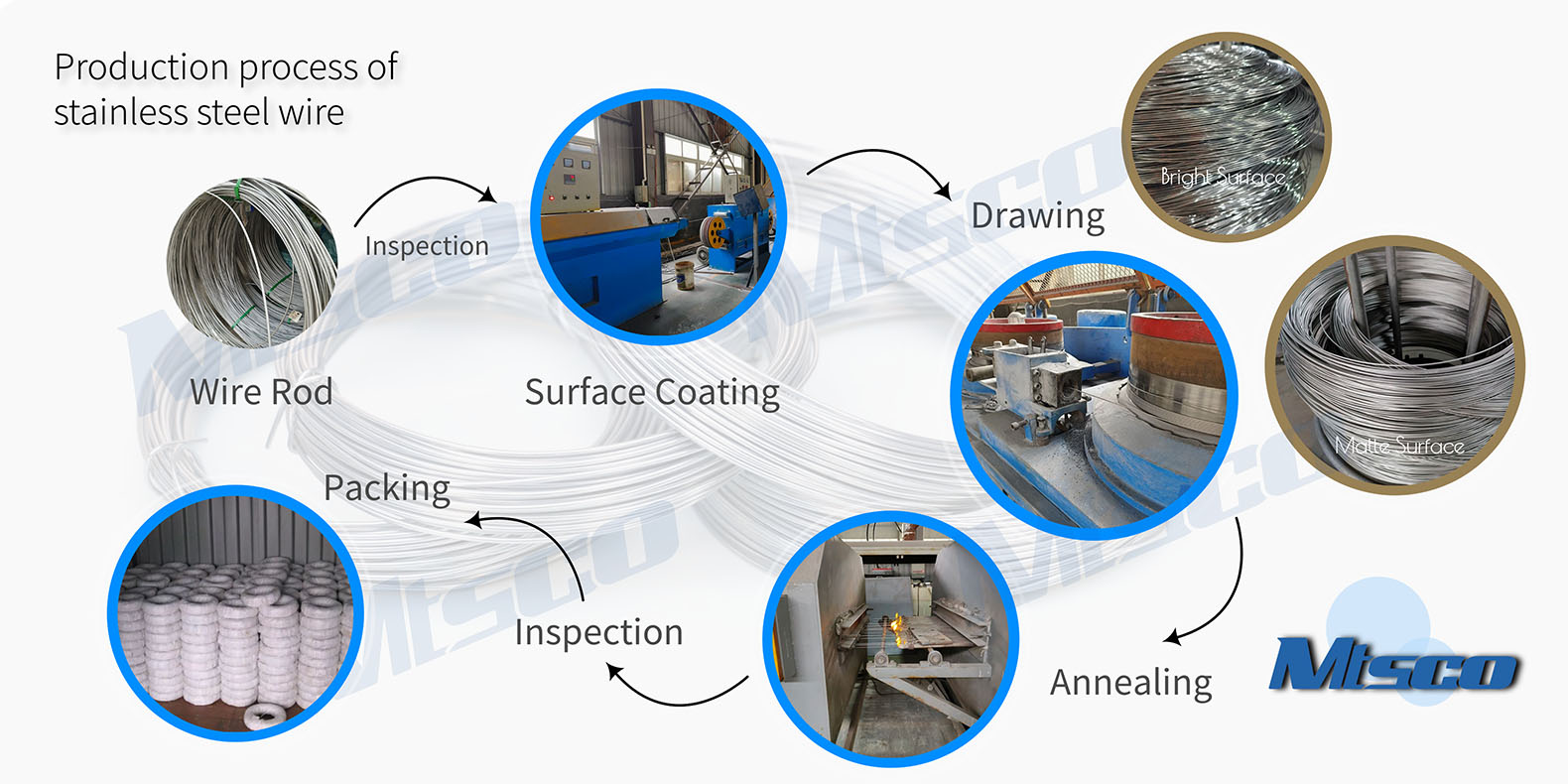

Mtsco is a professional steel wire supplier with complete production technology and rich management experience. We have 17 years of production experience, our annual productivity is more than 60000 tons. Mtsco is committed to the professional production of spring wire for automobile and machinery. In addition, we can provide electro polishing quality wire, mesh wire, annealed wire, welding wire, cold heading, locking wire, etc. The main materials are stainless steel and alloy steel. The raw materials used are from the largest well-known steel mills in China. We can provide wire products with sizes and diameters ranging from 0.15 mm to 16 mm, and strictly comply with ASTM, DIN, GTB, JIS, JSG and other international standards.

In addition to conventional standard size, we can also customize special-shaped and non-standard steel wire according to customer requirements.

MTSCO wire passed ISO9001 quality system in 2010 and introduced ERP system integrating management and information technology. We also passed the IOS/TS16949 International Automobile Industry Quality Management System, and all materials have passed the SGS test.

Quality Control

Why Choose MTSCO?

Integration of industry and trade

Provide you with cost-effective products and professional services.

One stop procurement of stainless steel wire products

Leave the complexity to Mtsco and the simplicity to you.

After the test of time for 17 years

Whether the products, services, capital and strength, Mtsco is your optimum partner.

Send Inquiry

*Required fields are marked.