Cold Heading Wire

Cold Heading Wire 1018 / 1023 / 1020 Wire Rope NUT for Bolt Fasteners Push Plates

Cold Heading Wire 1018 Wire Rope NUT Wire With High Strength

Mtsco is a professional steel wire supplier with complete production technology and rich management experience. We have 17 years of production experience, our annual productivity is more than 60000 tons. Mtsco is committed to the professional production of spring wire for automobile and machinery. In addition, we can provide electro polishing quality wire, mesh wire, annealed wire, welding wire, cold heading, locking wire, etc. The main materials are stainless steel and alloy steel. The raw materials used are from the largest well-known steel mills in China. We can provide wire products with sizes and diameters ranging from 0.15 mm to 16 mm, and strictly comply with ASTM, DIN, GTB, JIS, JSG and other international standards.

In addition to conventional standard size, we can also customize special-shaped and non-standard steel wire according to customer requirements.

MTSCO wire passed ISO9001 quality system in 2010 and introduced ERP system integrating management and information technology. We also passed the IOS/TS16949 International Automobile Industry Quality Management System, and all materials have passed the SGS test.

| Product name | Cold Heading Wire | |||

| Product material | ASTM 1566, 9260, 6150, 1070, 1035, 1045,1018, 1020, 1022, 1023, SAE9254, 55SiCrA, SWRH72A, SWRH72B, SCM435, SCM432... | |||

| Product use | Clutch spring, suspension spring, valve spring, etc. | |||

| Product standard | ASTMA229/A230/A401/A877/A580/A510/A29, GTB/18983-2017, EN10270-2, DIN17223-2, JSG3560/3561, etc. | |||

| Product diameter | φ1.8mm -φ16mm | |||

| Product cross section | Special-shaped steel bars with circular and various non-circular sections | |||

ASTM 1018 is suitable for manufacturing small and medium-sized parts with high surface hardness and low core requirements in automobile and general machinery manufacturing industries, such as handbrake shoes and lever shafts on automobiles; In the heavy and medium-sized machinery manufacturing industry, such as forged or pressed pull rods, levers, clamps, etc; It is used to manufacture various mechanical parts with low stress and high toughness under hot rolling or normalizing conditions

|  |

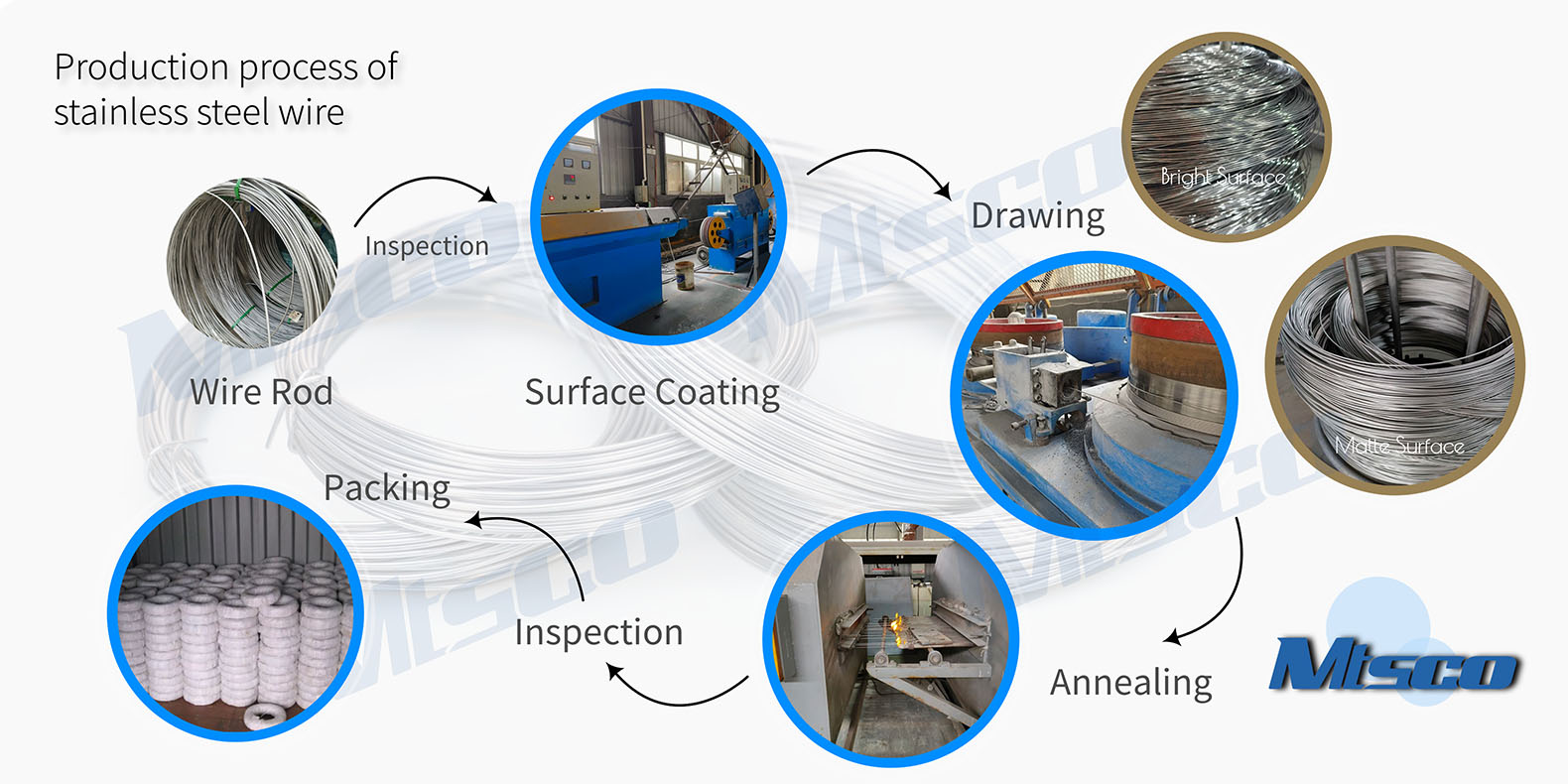

Quality Control

Quality Control

Why Choose MTSCO?

Integration of industry and trade

Provide you with cost-effective products and professional services.

One stop procurement of stainless steel wire products

Leave the complexity to Mtsco and the simplicity to you.

After the test of time for 17 years

Whether the products, services, capital and strength, Mtsco is your optimum partner.

Send Inquiry

*Required fields are marked.