Stainless Steel Spring Wire

ASTM A313 201/202/204Cu Stainless Steel Spring Wire 630 / 631 with Matte Surface

MTSCO can provide stainless steel and alloy steel spring wire with the diameter of 0.15-16mm, mainly grades are 300 series (301, 302, 304, 316, 321...) 130M, 200CU, 65Mn, 70#, 72A, 72B, 55SiCr, 50CrVA, etc. Our raw materials come from well-known steel mill in China, such as Yongxing, Baosteel,etc.

ASTM A313 201/202/204Cu Stainless Steel Spring Wire with Matte Surface

| Material | Stainless Steel Wire |

| Grade | 300series (301, 302, 303, 304, 304L, 304H, 304N, 304ES, 316L, 321,317, 317L...) 130M, 200CU, 201CU, 202, , 410, 420, 430,etc |

| Standard | ASTM A580, JIS G4309, EN 10088-3, GB/T4240, etc |

| Size | φ0.15mm-φ16mm; or according to customers' requests |

| Surface | Bright, matte ,downy, electrolysis bright ,cloudy ,plain ,black,etc |

| Condition | Annealed and Soft, 1/2 hard, 3/4 hard and full hard |

| Type | Spring Wire (B-SPR/D-SPR) |

| Packing | Woven bag, core, wooden reel, etc |

Advantages of stainless steel wire:

3. Highly elastic and impact resistant to fire

|  |

MTSCO can provide stainless steel and alloy steel spring wire with the diameter of 0.15-16mm, mainly grades are 300 series (301, 302, 304, 316, 321...) 130M, 200CU, 65Mn, 70#, 72A, 72B, 55SiCr, 50CrVA, etc. Our raw materials come from well-known steel mill in China, such as Yongxing, Baosteel,etc. Stainless steel spring wire has high corrosion resistance and good tensile strength. It is mainly used in spray springs, compression springs, tension springs, torsion springs, high-strength and high fatigue springs, medical springs, braided springs and other related fields.

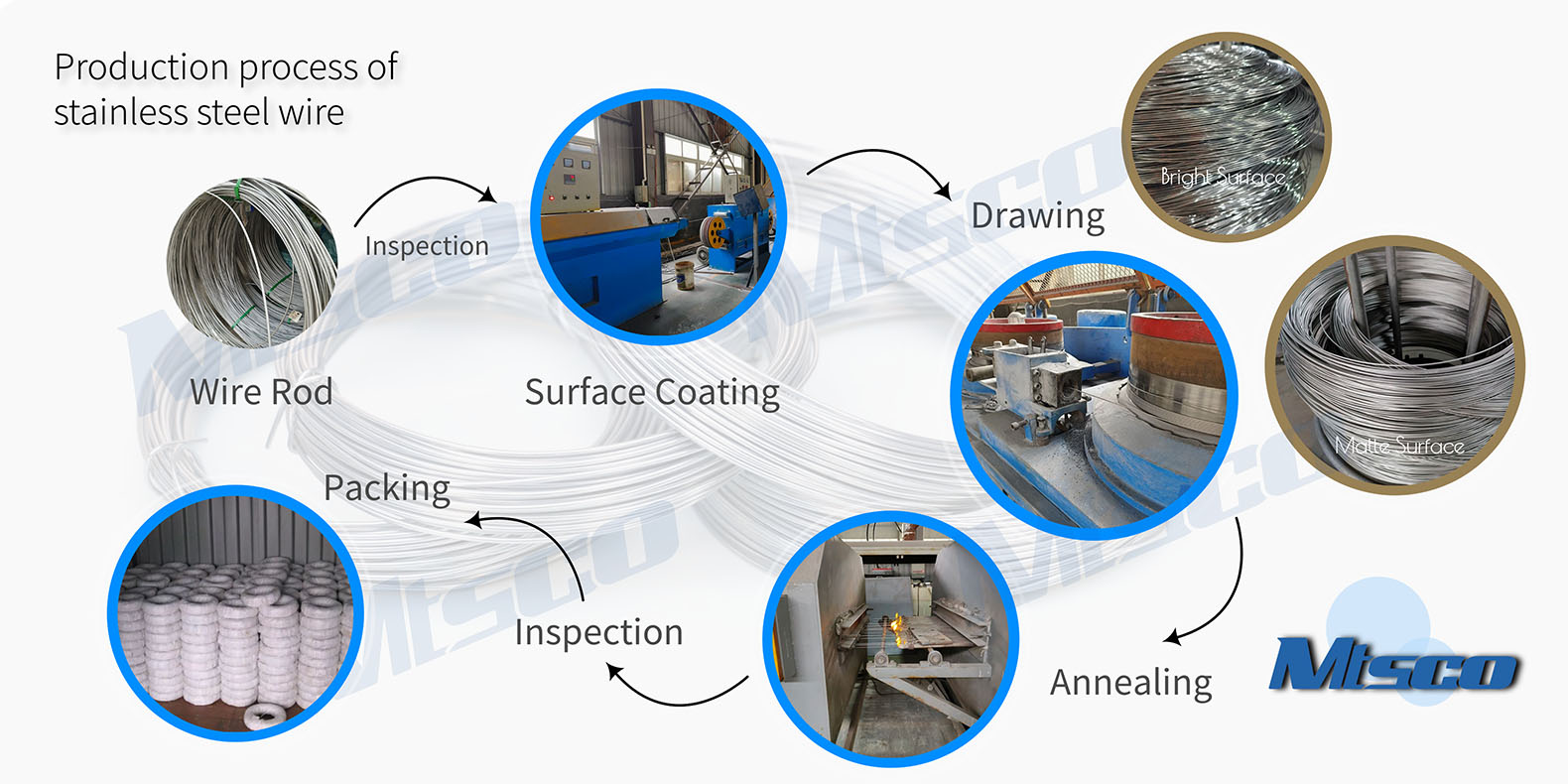

Quality Control

Why Choose MTSCO?

Integration of industry and trade

Provide you with cost-effective products and professional services.

One stop procurement of stainless steel wire products

Leave the complexity to Mtsco and the simplicity to you.

After the test of time for 17 years

Whether the products, services, capital and strength, Mtsco is your optimum partner.

Send Inquiry

*Required fields are marked.