Tig Welding Wire

ERNiCrMo-17 Nickel Alloy Tig Welding Consumables Welding Wire

ERNiCrMo-17 Nickel Alloy Tig Welding Wire is a super nickel-based alloy wire for TIG welding. This wire has a very high nickel content and has excellent welding properties, high temperature and corrosion resistance.

ERNiCrMo-17 Nickel Alloy Tig Welding Wire

| Material | Nickel Alloy Wire |

| Grade | Alloy 600, 601, 625, X-750, 718, C2000, C22, C276, C4, X, 400... |

| Standard | ASTM B166/B446/B637/B574/AME4730 |

| Size | φ0.15mm-φ16mm; Or According To Customers' Requests |

| Type | Round, flat, core, braiding, staple |

| Condition | Annealed and Soft, 1/2 hard, 3/4 hard and full hard |

| Packing | Woven bag, core, wooden reel, etc |

Features of Nickel Alloy Welding Wire:

- Excellent corrosion resistance: able to provide reliable welded connections in a wide range of corrosive media.

- Excellent mechanical properties: nickel alloy wire has high strength, good ductility and fatigue resistance to ensure the stability and reliability of welded joints.

- Stability at high temperatures: Nickel alloy wires maintain stable weld performance at high temperatures, resisting the challenges of high temperature corrosion and thermal stress.

Application:

1. Aerospace: manufacture and maintenance of aero-engines, gas turbines, aeronautical components and so on. Their high-temperature oxidation resistance, corrosion resistance and high strength enable them to withstand the extreme environments and stresses required under high temperature conditions.

2. Oil and gas industry: the manufacture and maintenance of oil well pipelines, storage tanks, furnace pipes, etc.. Its corrosion resistance and high temperature performance enables it to withstand the harsh working environment and corrosive media, to ensure the reliable operation of equipment.

3. Chemical industry: manufacture and maintenance of equipment such as reactors, heat exchangers, distillation columns, etc.. Its corrosion resistance and oxidation resistance make it able to resist the harsh conditions of strong acid, strong alkali and high temperature to ensure the safety and stability of the industrial process.

4. Nuclear energy industry: nickel nuclear reactor, nuclear power plant and other equipment manufacturing and maintenance. Its radiation resistance and high temperature performance enable it to withstand the challenges of the nuclear energy environment and ensure the safe operation of nuclear facilities.

5. Manufacturing industry: manufacturing and maintenance of various high-temperature equipment, chemical equipment, electronic equipment, automotive parts, etc.. Its excellent performance and reliability enable it to meet a variety of engineering needs.

Quality Assurance:

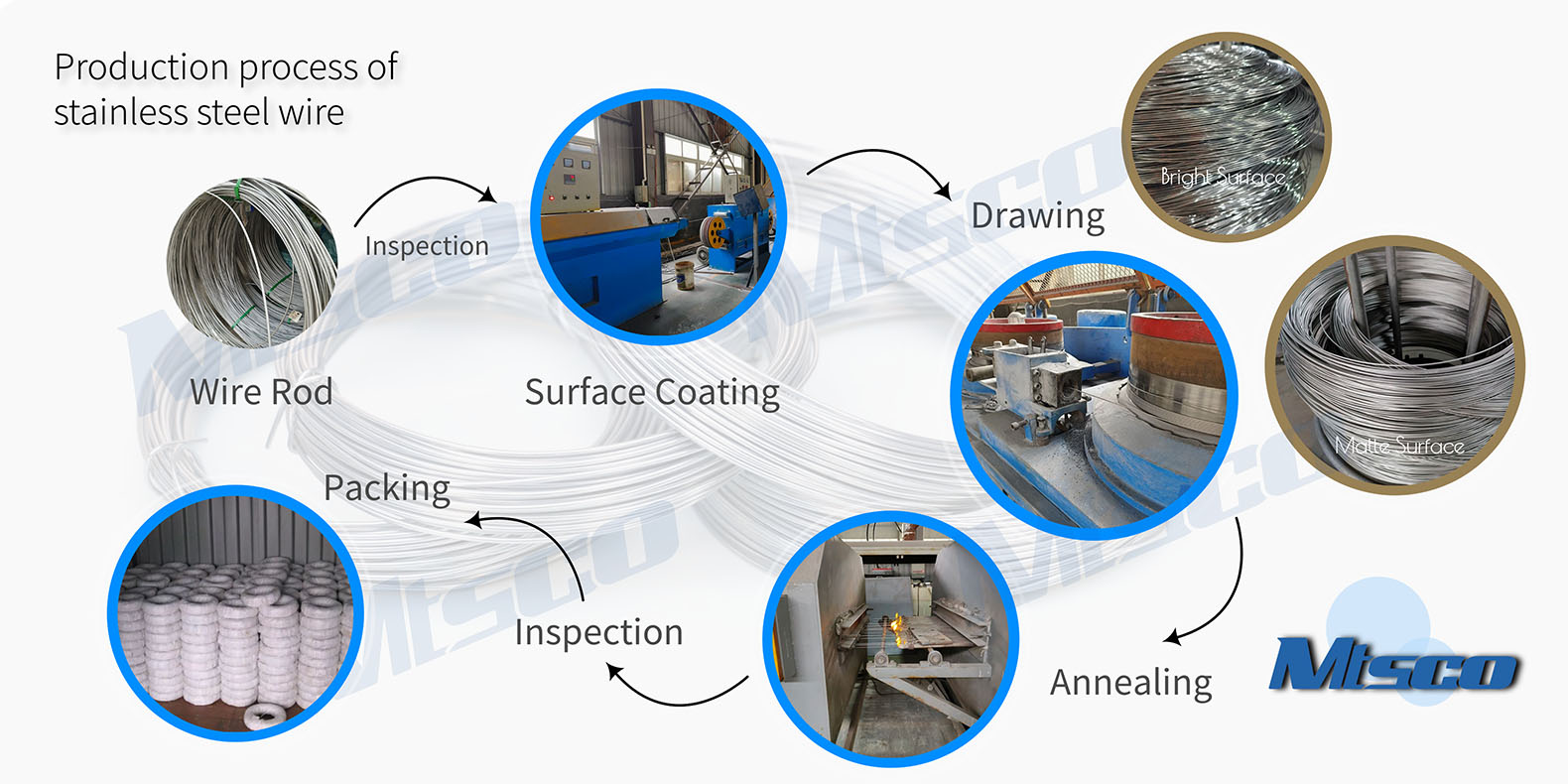

Initial Stage: Verification of Material Test Certificates (PMI), Evaluation of Tensile Strength, Examination of Surface/Dimensions

During Manufacturing: Designated personnel oversee and validate in alignment with the production process chart, retaining a duplicate for records.

Pre-Dispatch: Assessment of Mechanical Attributes, Review of Surface/Dimensions, or as stipulated by the client's specifications.

Raw Material Quality Assurance:

Even minor variations in the chemical composition and mechanical attributes of raw materials can greatly influence the characteristics of the final steel wire. Consequently, the foundational bar's quality plays a pivotal role in defining the caliber of the completed steel wire. We enforce rigorous evaluations of raw materials. Only those materials that successfully pass our stringent checks and align with established standards progress to subsequent phases.

Company Profile:

Mtsco is a professional supplier of steel wire with 17 years of experience, complete production technology, and extensive management experience. We have an exclusive manufacturer: XINHANG WIRE. MTSCO has entered into a highly strategic partnership with XINHANG WIRE as the only international trade center of XINHANG WIRE. Mtsco specializes in spring steel wire, nickel alloy wire, welding wire, and shaped wire. In addition, we can supply electro-polishing quality wire, mesh wire, annealed wire, cold heading wire, locking wire, etc. The primary materials are nickel alloy, stainless steel, carbon steel, and alloy steel. Our products are widely used in the automotive and machinery fields, petrochemical, pipeline, valve, pressure vessel, power plant, chemical equipment field, nuclear power field, communication, and electronic machinery field, etc.