Nickel Alloy Spring Wire

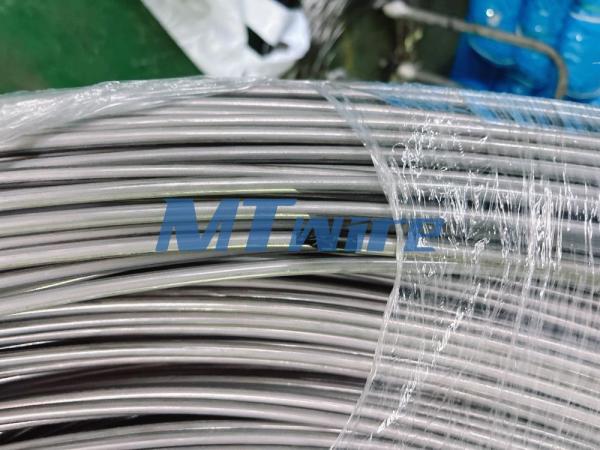

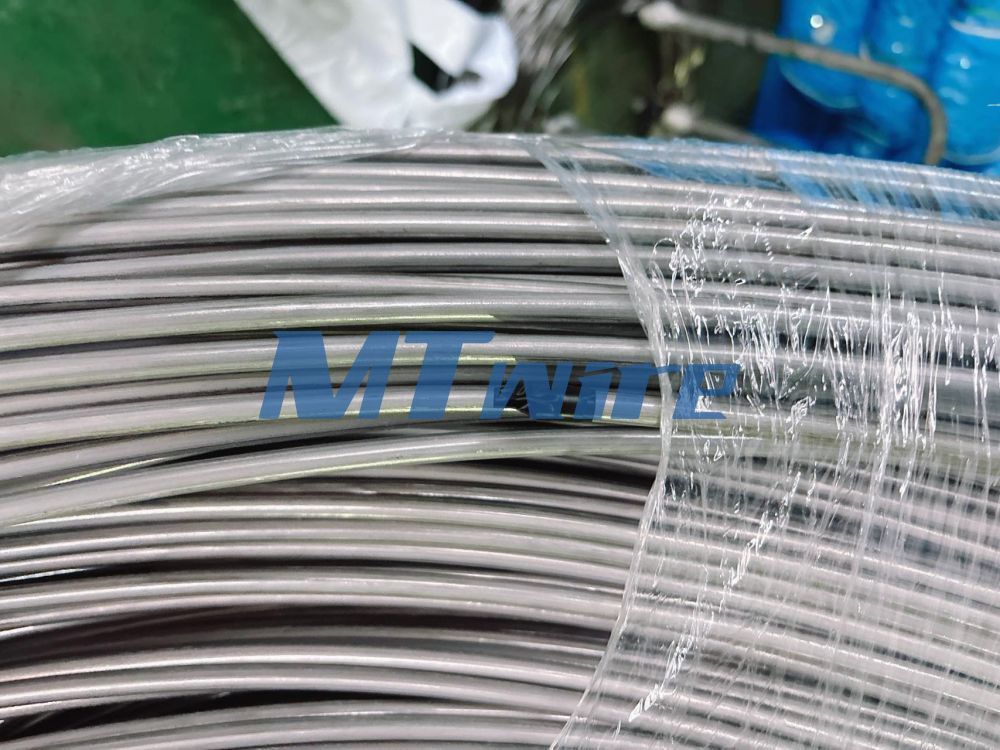

ASTM B425 Nickel Alloy 825 / 800 / C276 Spring Wire For Marine Engineering

Nickel Alloy 825 Spring Wire, is a high-performance alloy spring wire composed of nickel, chromium, copper, and titanium. It has excellent corrosion resistance and high-temperature stability for harsh operating environments. This spring wire has excellent elasticity and tensile strength and can manufacture corrosion-resistant spring components such as valve springs and pump springs. It also has good weldability and processability and can be used in various processing techniques to meet different engineering needs. Whether in the chemical, aerospace, marine engineering, or energy fields, Nickel Alloy 825 Spring Wire has demonstrated excellent performance and reliability.

ASTM B425 Nickel Alloy 825 Spring Wire For Marine Engineering

Chemical Composition:

| Nickel Alloy | Ni | Cr | Fe | Mn | C | Cu | Si | S | P | Co | Nb/Cb | Ti |

| Alloy 600 | >=72 | 14-17 | 45087 | 1 | 0.1 | 0.5 | 0.5 | 0.015 | 0.04 | 1 | 1 | 0.5 |

| Alloy 601 | 58-63 | 21-25 | bal | 1 | 0.1 | 1 | 0.5 | 0.015 | - | - | - | - |

| Alloy 625 | >=58 | 20-23 | 5 | 0.5 | 0.1 | 0.5 | 0.5 | 0.015 | 0.015 | 1 | 3.15-4.15 | 0.4 |

| Alloy X-750 | >=70 | 14-17 | 5.0-9.0 | 1 | 0.08 | 0.5 | 0.5 | 0.01 | - | 1 | 0.7-1.2 | 2.25-2.75 |

| Alloy 718 | 50-55 | 17-21 | bal | 0.35 | 0.08 | 0.3 | 0.35 | 0.015 | 0.015 | 1 | 4.75-5.5 | 0.65-1.15 |

| Alloy 800 | 30-35 | 19-23 | bal | 1.5 | 0.1 | 0.75 | 1 | 0.015 | - | 2 | - | 0.15-0.6 |

| Alloy 800HT | 30-35 | 19-23 | bal | 1.5 | 0.05-0.1 | 0.75 | 1 | 0.015 | - | 2 | - | 0.15-0.6 |

| Alloy 825 | 38-46 | 19.5-23.5 | bal | 1 | 0.05 | 1.5-3.0 | 0.5 | 0.03 | - | 2 | - | 0.6-1.2 |

| Alloy C-4 | bal | 14-18 | 3 | 1 | 0.015 | - | 0.08 | 0.03 | 0.04 | 2 | - | 0.7 |

| Alloy C-22 | bal | 20-22.5 | 44963 | 0.5 | 0.015 | - | 0.08 | 0.02 | 0.02 | 2.5 | - | - |

| Alloy C-276 | bal | 14.5-16.5 | 45023 | 1 | 0.01 | - | 0.08 | 0.03 | 0.04 | 2.5 | - | - |

| Alloy C-2000 | bal | 22-24 | 3 | 0.5 | 0.01 | 1.3-1.9 | 0.08 | 0.01 | 0.025 | 2 | - | - |

| Alloy X | bal | 20.5-23 | 17-20 | 1 | 0.05-0.15 | - | 1 | 0.03 | 0.04 | 0.5-2.5 | - | - |

| Alloy 400 | 63-70(Ni+Co) | - | 2.5 | 2 | 0.3 | 28-34 | 0.5 | 0.024 | - | 2 | - | - |

Advantageous features of Spring Wire:

Main application areas:

7. Aerospace: Spring Wire is used for spring components in aircraft and spacecraft to meet the stringent aerospace requirements.

Quality control of raw materials:

Raw Material Quality Assurance:

Quality Control

Why Choose MTSCO?

Integration of industry and trade

Provide you with cost-effective products and professional services.

One stop procurement of stainless steel wire products

Leave the complexity to Mtsco and the simplicity to you.

After the test of time for 17 years

Whether the products, services, capital and strength, Mtsco is your optimum partner.

Send Inquiry

*Required fields are marked.