Nickel Alloy Spring Wire

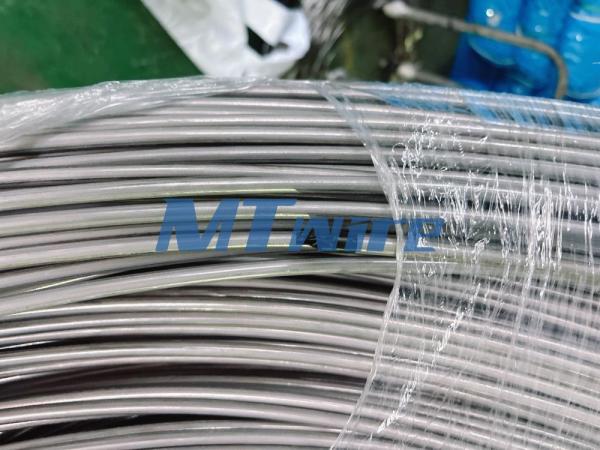

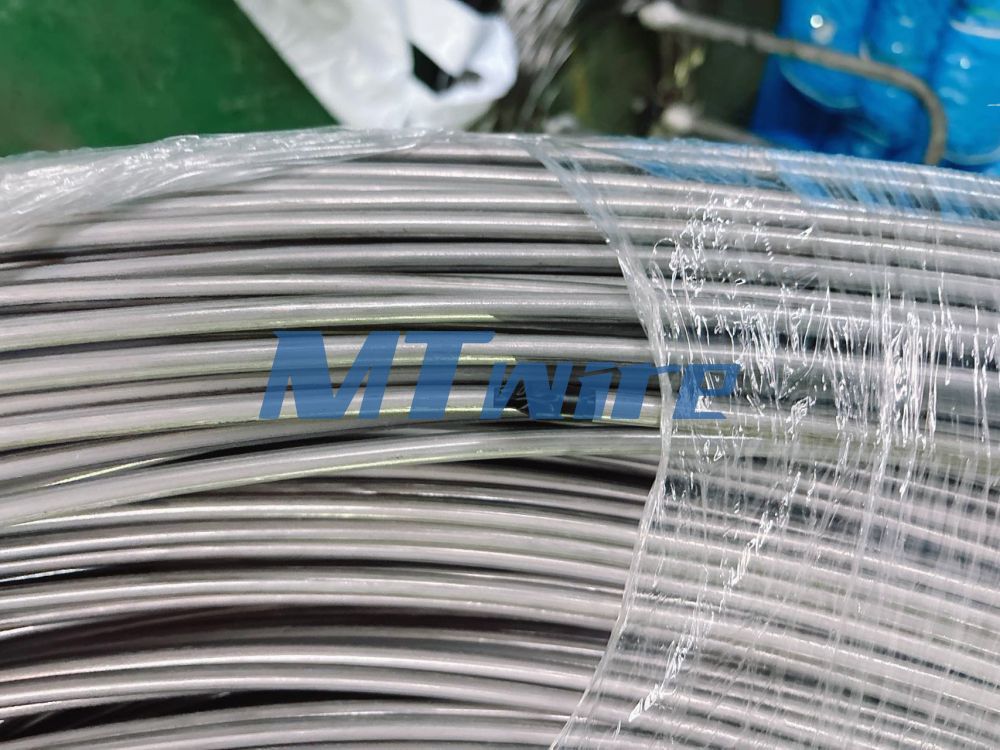

UNS N07750 Nickel Alloy X-750 Spring Wire For Automotive / Aerospace / Medical Devices

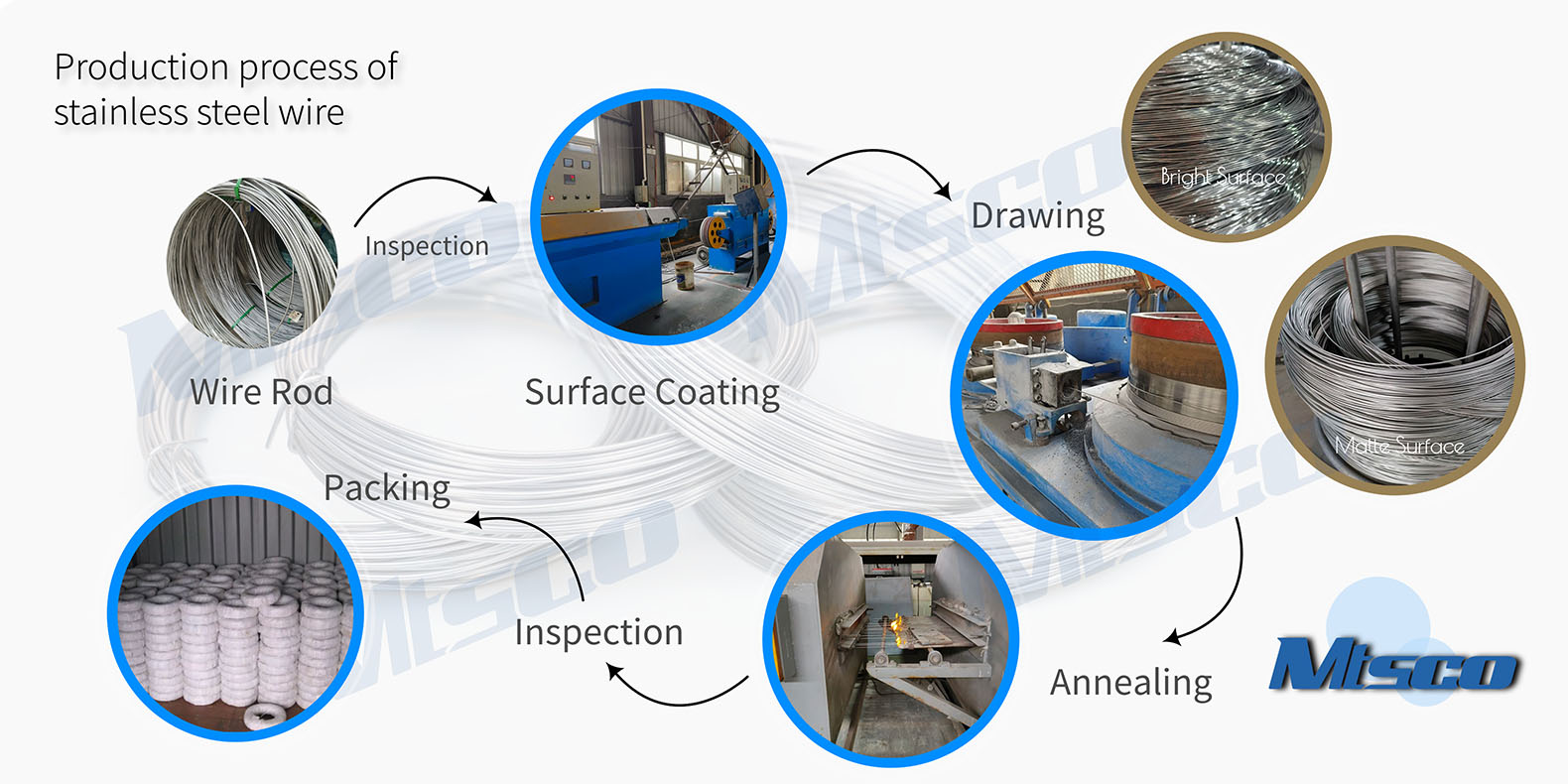

Mtsco is a professional supplier of steel wire with 17 years of experience, complete production technology, and extensive management experience. Mtsco is dedicated to specializing in spring steel wire, nickel alloy wire, welding wire, and shaped wire. In addition, we can supply electro-polishing quality wire, mesh wire, annealed wire, cold heading wire, locking wire, etc. The main materials are nickel alloy, stainless steel, carbon steel, and alloy steel. Our products are widely used in the automotive and machinery fields, petrochemical, pipeline, valve, pressure vessel, power plant, chemical equipment field, nuclear power field, communication and electronic machinery field, etc.

Nickel Alloy Spring Wire For Automotive / Aerospace / Medical Devices

What is nickel alloy spring steel wire?

Nickel Alloy Spring Wire, known for its outstanding corrosion resistance and excellent spring properties, is a high-quality wire product. It is widely used in various industries, including automotive, aerospace, and medical, where precision and reliability are paramount. With its nickel-based alloy composition, this wire offers exceptional strength, durability, and flexibility. Whether it's for springs, fasteners, or other critical components, Nickel Alloy Spring Wire provides superior performance and long-lasting functionality.

| Material | Nickel Alloy Wire |

| Grade | Alloy 600, 601, 625, X-750, 718, C2000, C22, C276, C4, X, 400... |

| Standard | ASTM B166/B446/B637/B574/AME4730 |

| Size | φ0.15mm-φ16mm; Or According To Customers' Requests |

| Type | Round, flat, core, braiding, staple |

| Condition | Annealed and Soft, 1/2 hard, 3/4 hard and full hard |

| Packing | Woven bag, core, wooden reel, etc |

Chemical Composition

| Nickel Alloy | Ni | Cr | Fe | Mn | C | Cu | Si | S | P | Co | Nb/Cb | Ti | Ta | Al | Mo | B | Pb | Bi | Se | W | V |

| Alloy 600 | >=72 | 14-17 | 45087 | 1 | 0.1 | 0.5 | 0.5 | 0.015 | 0.04 | 1 | 1 | 0.5 | 0.05 | 0.35 | - | ||||||

| Alloy 601 | 58-63 | 21-25 | bal | 1 | 0.1 | 1 | 0.5 | 0.015 | - | - | - | - | - | 1-1.7 | - | ||||||

| Alloy 625 | >=58 | 20-23 | 5 | 0.5 | 0.1 | 0.5 | 0.5 | 0.015 | 0.015 | 1 | 3.15-4.15 | 0.4 | 0.05 | 0.4 | 8-10 | ||||||

| Alloy X-750 | >=70 | 14-17 | 5.0-9.0 | 1 | 0.08 | 0.5 | 0.5 | 0.01 | - | 1 | 0.7-1.2 | 2.25-2.75 | 0.05 | 0.4-1.0 | - | ||||||

| Alloy 718 | 50-55 | 17-21 | bal | 0.35 | 0.08 | 0.3 | 0.35 | 0.015 | 0.015 | 1 | 4.75-5.5 | 0.65-1.15 | 0.05 | 0.2-0.8 | 2.8-3.3 | 0.006 | 0.0005 | 3E-05 | 0.003 | ||

| Alloy 800 | 30-35 | 19-23 | bal | 1.5 | 0.1 | 0.75 | 1 | 0.015 | - | 2 | - | 0.15-0.6 | - | 0.15-0.6 | - | ||||||

| Alloy 800HT | 30-35 | 19-23 | bal | 1.5 | 0.05-0.1 | 0.75 | 1 | 0.015 | - | 2 | - | 0.15-0.6 | - | 0.15-0.6 | - | ||||||

| Alloy 825 | 38-46 | 19.5-23.5 | bal | 1 | 0.05 | 1.5-3.0 | 0.5 | 0.03 | - | 2 | - | 0.6-1.2 | - | 0.2 | - | ||||||

| Alloy C-4 | bal | 14-18 | 3 | 1 | 0.015 | - | 0.08 | 0.03 | 0.04 | 2 | - | 0.7 | - | - | 14-17 | - | - | - | |||

| Alloy C-22 | bal | 20-22.5 | 44963 | 0.5 | 0.015 | - | 0.08 | 0.02 | 0.02 | 2.5 | - | - | - | - | 12.5-14.5 | - | 2.5-3.5 | 0.35 | |||

| Alloy C-276 | bal | 14.5-16.5 | 45023 | 1 | 0.01 | - | 0.08 | 0.03 | 0.04 | 2.5 | - | - | - | - | 15-17 | - | 3-4.5 | 0.35 | |||

| Alloy C-2000 | bal | 22-24 | 3 | 0.5 | 0.01 | 1.3-1.9 | 0.08 | 0.01 | 0.025 | 2 | - | - | - | 0.5 | - | - | - | - | |||

| Alloy X | bal | 20.5-23 | 17-20 | 1 | 0.05-0.15 | - | 1 | 0.03 | 0.04 | 0.5-2.5 | - | - | - | - | 45148 | 0.01 | 0.2-1.0 | - | |||

| Alloy 400 | 63-70(Ni+Co) | - | 2.5 | 2 | 0.3 | 28-34 | 0.5 | 0.024 | - | 2 | - | - | - | - | - | - |

Nickel Alloy Spring Wire Features:

Nickel Alloy Spring Wire Application:

Factory advantages:

Quality Control:

Before shipment: Mechanical properties test, Surface/Dimension inspection, or according to customers’ requirement

Company Profile:

Quality Control

Why Choose MTSCO?

Integration of industry and trade

Provide you with cost-effective products and professional services.

One stop procurement of stainless steel wire products

Leave the complexity to Mtsco and the simplicity to you.

After the test of time for 17 years

Whether the products, services, capital and strength, Mtsco is your optimum partner.

Send Inquiry

*Required fields are marked.