Wedge Wire

Stainless Steel Coanda Screen Wire Nickel Alloy Wedge Wire

MTSCO is a professional supplier of steel wire specializing in the production of wedge wire, along with a variety of other products including spring wire, shaped wire, nickel alloy wire, welding wire, electrolytically polished wire, fine wire, netting wire, hose wire, cold heading wire, and locking wire. We prioritize wedge wire due to its critical application in filtering and screening technologies across various industries. Our core materials encompass stainless steel, nickel alloy, and alloy steel, sourced from the largest and most reputable steel mills in China.

Stainless Steel Coanda Screen Wire Nickel Alloy Wedge Wire

Standard Wire surface:

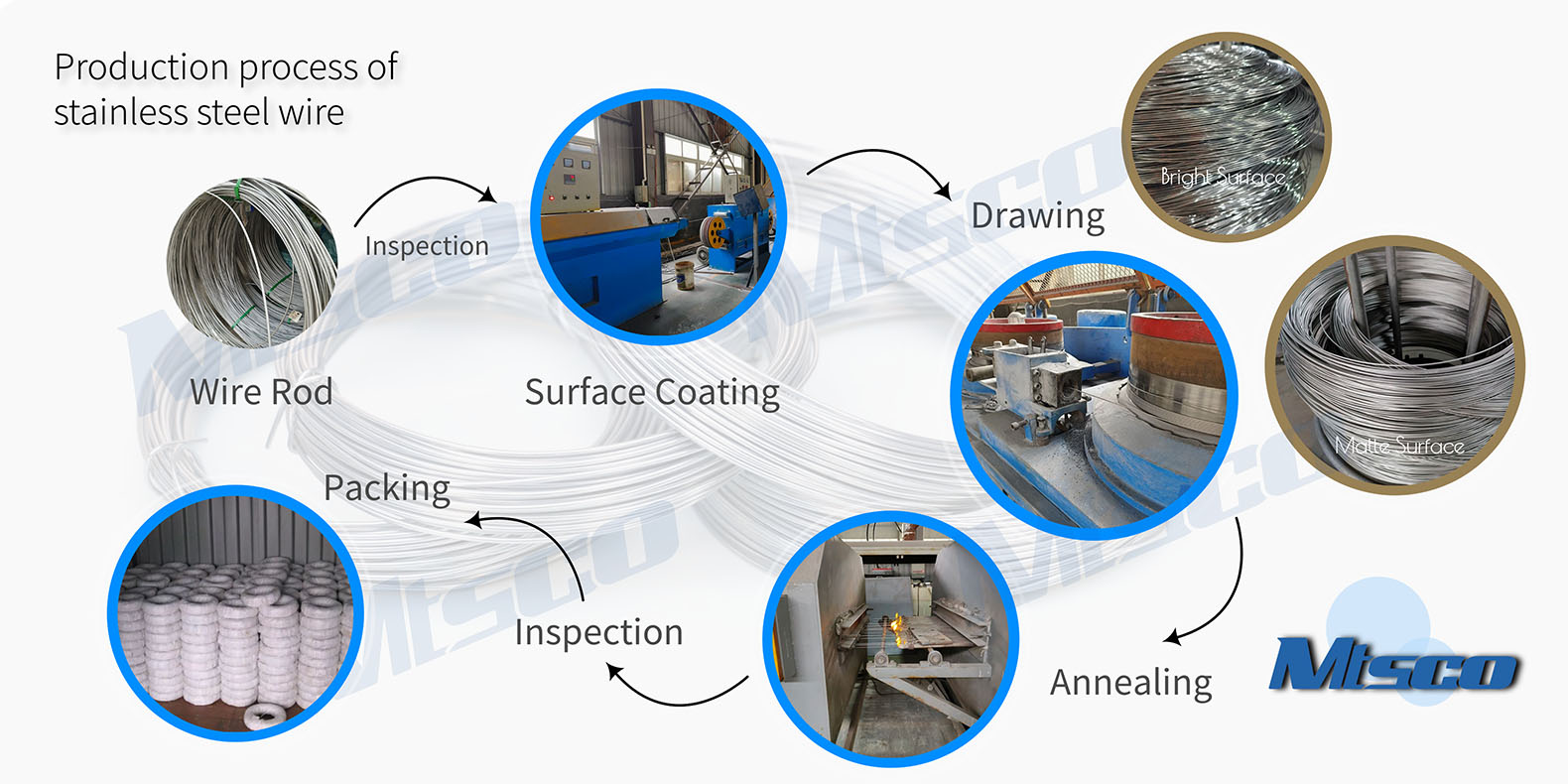

Production process

Quality Control:

Product Packaging

- 50kg/coil, Coils In Bundle

- 100kg/coil, Coils In Bundle

- 100kg/coil, Coils On Pallet

- 200kg/core Core On Pallet

- 400kg/core

- Cores, On Carrier

Quality Control

Why Choose MTSCO?

Integration of industry and trade

Provide you with cost-effective products and professional services.

One stop procurement of stainless steel wire products

Leave the complexity to Mtsco and the simplicity to you.

After the test of time for 17 years

Whether the products, services, capital and strength, Mtsco is your optimum partner.

Send Inquiry

*Required fields are marked.