Mig Welding Wire

Nickel Alloy ER601 / ER600 / ER625 Welding Wire With ISO PED For Aerospace Industry

Nickel Alloy 601 Welding Wire consists of elements such as nickel, chromium and iron and is a high-temperature corrosion-resistant alloy wire with excellent corrosion resistance and high-temperature performance. It is capable of maintaining strength and durability at high temperatures and resisting a wide range of corrosive media. The wire is widely used in the petrochemical and chemical industries and aerospace. It is used in the manufacture of high-temperature components such as oil extraction equipment, chemical reactors and gas turbines, as well as combustion chambers and turbine blades in aircraft engines.

Nickel Alloy ER601 Welding Wire With ISO PED For Aerospace Industry

Grade | Alloy 600 /N06600, Alloy 601/N06601, Alloy 625, X-750, 718, C2000, C22, C276, C4, X, 400... |

Standard | ASTM B166; ASTM B446; ASTM B670; ASTM B335;ASTM B637; ASTM B574; ASTM B408; ASTM B425 , etc |

Surface | Bright Annealed/ Annealed Pickled |

Technology | Cold Drawing |

NDT | Ultrasonic test |

Inspection | 100% |

Packing | Pallet/ Plywooden case/ Wooden Reel |

Quality Assurance | ISO & PED |

Bar/ Rod | Wire | |

Outer Diameter | ≥10mm | 2mm-5.5mm |

Length | ≤12000mm | - |

Weight | - | ≤350KGS |

Advantages of Nickel Alloy ER601 Welding Wire:

Application of Nickel Alloy ER601 Welding Wire:

|  |

Quality control of raw materials

Slight changes in the chemical composition and mechanical properties of raw materials will have a significant impact on the properties of finished steel wire. Therefore, the quality of base bar is one of the key factors to determine the quality of finished steel wire. We will strictly test the raw materials. Only raw materials that pass the test and meet the standards can go to the next process.

Quality Control

Raw Materials: MTC checking(PMI), Tensile strength test, Surface/Dimension inspection

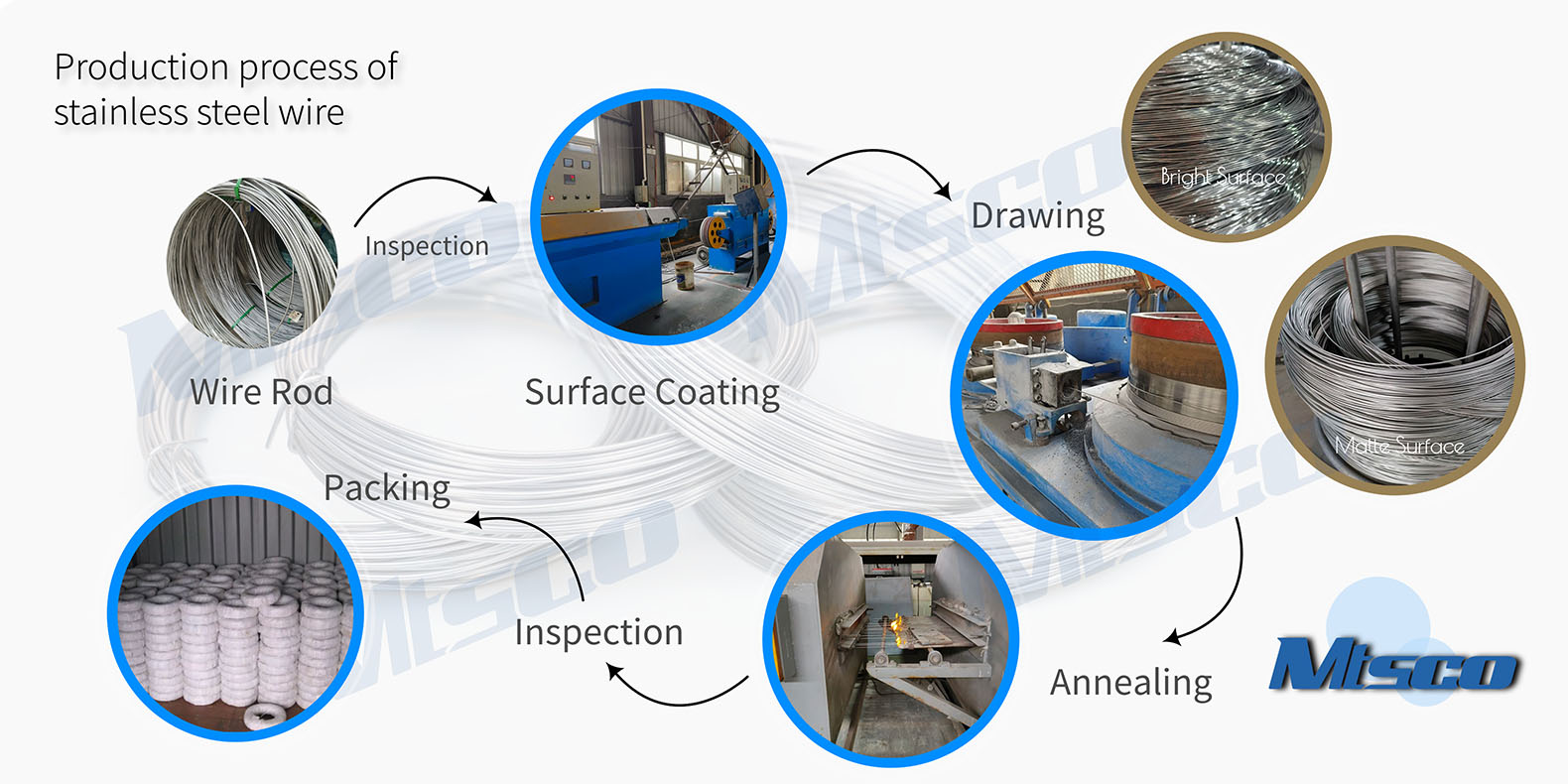

Production: The specially assigned person shall follow up and check according to the process flow card, and finally keep the copy

Before shipment: Eddy current surface flaw detection, 30 times magnifying glass surface inspection, salt spray test, tensile test, winding test, torsion number test

Company Profile:

Quality Control

Why Choose MTSCO?

Integration of industry and trade

Provide you with cost-effective products and professional services.

One stop procurement of stainless steel wire products

Leave the complexity to Mtsco and the simplicity to you.

After the test of time for 17 years

Whether the products, services, capital and strength, Mtsco is your optimum partner.

Send Inquiry

*Required fields are marked.